Auto

Semiconductor crisis will be over by 2022: Elon Musk

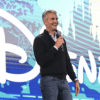

Elon Musk believes the chip shortage is a short-term problem as opposed to a long-term one, and the ongoing semiconductor crisis will be over by next year. The Tesla CEO, at an Italian tech event that was streamed online, highlighted that there are a lot of chip fabrication plants that are being built.

The global chip shortage has had a major impact on a wide range of industries, but the automotive sector has been badly impacted. Big names such as Ford, Volkswagen and Daimler have all been forced to suspend production at various points and cut their manufacturing targets as a result of a lack of chips.

AlixPartners, a consulting firm, predicted that the chip shortage will cost the automotive industry $210 billion in revenue this year alone. Mark Wakefield, global co-leader of the automotive and industrial practice, AlixPartners, in a statement said everyone had hoped that the chip crisis would have abated more by now, but unfortunately events such as the COVID-19 lockdowns in Malaysia and continued problems elsewhere have exacerbated things.

AlixPartners forecasts that 7.7 million units of production will be lost in 2021, up from 3.9 million in its May forecast – the biggest hit to production occurred in the second quarter. “The second quarter of this year is still the worst of chip shortage so far in terms of lost vehicles. But what’s changed is that the auto industry globally simply hasn’t recovered as quickly as we thought when we did our forecast in May due to unforeseen things since then like the rise of the delta variant and the COVID breakouts in Malaysia and Southeast Asian countries,” it said.

Glenn O’Donnell, vice-president research director at Forrester, believes the shortage could last until 2023. “Because demand will remain high and supply will remain constrained, we expect this shortage to last through 2022 and into 2023.” The chips are used in a variety of car parts. The worldwide shortage started earlier this year, in part as a result of the COVID-19 pandemic. As people increasingly worked from home and children were home-schooled, the demand rose for the personal electronics that the chips are used in. And when automobile companies restarted their plants last year at the peak of the pandemic, the carmakers scrambled to make up lost vehicle production. They needed the chips too for the cars and soon enough, chipmakers could not keep pace with the demand.

Also Read: 75 artisans from 20 states to participate in 4-day Exim Bazaar from Oct 1

This has resulted in barren dealership lots of new-vehicle inventory, customers facing long waits and higher prices to buy a new car.

Pingback: TTSF Cloud One has launched Prowl Foods with Tiger Shroff.