Sneakers

Nike’s 3D-Printed Air Max 1000 Finally Drops — And the All-Black Pair Is a Showstopper

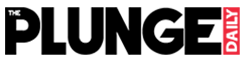

Nearly 40 years after Tinker Hatfield redefined sneaker culture with the visible Air unit, Nike is once again rewriting the rules. The long-awaited Nike Air Max 1000, a fully 3D-printed sneaker developed with German tech innovators Zellerfeld, is finally hitting the market on August 19 in two exclusive colorways: “Black” and “Oat.”

First teased at ComplexCon 2024, the Air Max 1000 merges the DNA of the original Air Max 1 with next-generation manufacturing. The result? A shoe that’s 103 grams lighter than comparable models, visually striking, and built entirely without glue, stitching, or a traditional assembly line.

Classic DNA Meets Futuristic Craftsmanship

The Zellerfeld developed Air Max 1000 keeps Nike’s iconic visible Air unit but pushes the design into new territory. The “Oat” version pairs warm tones with a bold “Total Orange” Air bubble, while the “Black” colorway swaps subtlety for an electric green pop. Both versions feature sculpted mudguard patterns integrated directly into Zellerfeld’s proprietary zellerFOAM TPU construction, giving the sneaker depth and texture no traditional mold could replicate.

Nike Air Max 1000 – Developed by German tech innovators Zellerfeld (Oat Color)

Laceless by design, the Air Max 1000 hugs the foot with an elastic slip-on structure. This approach not only updates the silhouette’s look but also streamlines how the shoe is worn, removing unnecessary components while enhancing comfort.

Game-Changing Printing Technology

Zellerfeld’s variable-density 3D-printing technique is more than a gimmick. By adjusting firmness and flexibility across different zones of the shoe, the process creates targeted support and movement. The fused filament fabrication method means fewer materials, faster production, and potentially more sustainable manufacturing.

In the “Black” edition, the monochromatic finish amplifies every sculpted ridge, geometric angle, and web-like detail, making it the most visually dramatic example of what 3D-printing can achieve.

View this post on Instagram

Release Details

The Nike Air Max 1000 retails for $179 and will be available in limited quantities. The “Oat” colorway drops via the SNKRS app at 10 AM PST in a 10-minute draw, while the “Black” version is exclusive to Zellerfeld’s website. Due to current 3D-printing constraints, only whole sizes will be produced — so sizing up by half is recommended.

Following a small early drop earlier this year, demand for the Air Max 1000 is expected to be intense. While exact production numbers remain under wraps, sneaker insiders anticipate these pairs will sell out within minutes.

A Glimpse Into the Future of Footwear

With the Air Max 1000, Nike is signaling more than just another collectible sneaker drop — it’s a preview of how footwear could be designed, manufactured, and personalized in the future. Just as the Air Max 1 changed the game in 1987, this 3D-printed evolution could mark the next major turning point in sneaker history.

Pingback: Scrap to Sports: Nike and Gallant Launch India’s First Green Turf