Manufacturing

IIT Kharagpur and TCS set new trend with Industry 4.0 technology

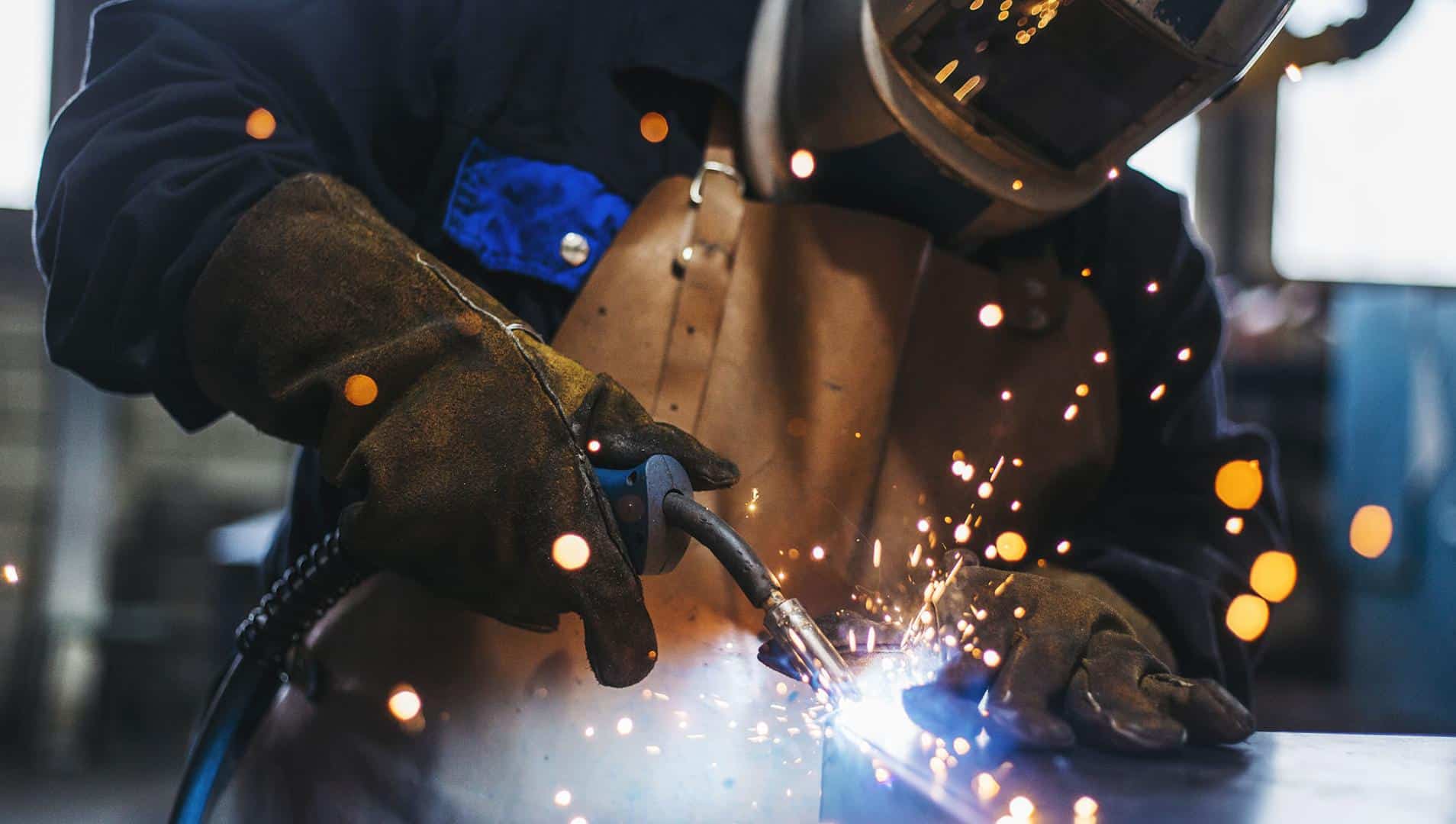

IIT Kharagpur, in partnership with TCS, has developed Industry 4.0 technology for remotely controlled factory operations and real-time quality correction during industrial production.

The innovative technology, developed by Prof. Surjya K Pal, Professor in-charge at the Center of Excellence in Advanced Manufacturing Technology in association with TCS, will acquire real-time information about the welding process through multiple sensors and enable online control of weld quality by means of cloud-based communication with the friction stir welding machine.

The present innovation upgrades the industrial process of friction stir wielding to a multi-sensory system of Industry 4.0. Besides setting the course for remotely controlled operations in the Indian industrial sector, it has enabled real-time quality check and correction during the production process. This will make possible for industrial houses to achieve standardized quality goals throughout the production process and reduce rejection, and lower the cost of production as well. And in this pandemic times, cloud infrastructure, remote and real-time operations systems hold the key to maintain effective industrial operations. As such, Director Professor Virendra K Tewari emphasized on the need for such technologies to achieve the Make in India goal. He said the primary goal should be the quality output with minimum disruptions. “Be it consumers in India or aboard, these are the two basic needs our industrial sector, which we must address for procuring orders in large volumes,” Tewari said. “At IIT Kharagpur’s Center for Excellence in Advanced Manufacturing Technology, we have set our target to bring to the forefront indigenously developed industry 4.0 technologies to support our industrial sector to achieve this goal.”

Prof. Pal pointed out that welding is at the heart of any industrial operations. “If we can improve the weld quality in real-time during batch production we can reduce rejections in post production sample checks,” he said. “Our multiple sensor process involves various signal processing and machine learning techniques to predict the ultimate tensile strength of the weld joint is fabricated.” Pal explained that the new technology is connected with a vast experimental knowledge base to conform to a standard system and prediction of the weld joint strength. “Any defect identified during the monitoring procedure is corrected in real-time by sending modified parameters to the machine, ensuring standardized quality of the process.” He said the concept of the technology can further be evolved for real-time control of other industrial processes.

Pingback: ISRO launches 10 satellites including primary payload EOS-01 | The Plunge Daily

Pingback: Aisle: high-intent dating app developed and designed by Indians for Indians | The Plunge Daily